Boosting Manufacturing Efficiency with Azure AI Custom Vision: Real-World Use Cases and Best Practices

In this Industry 4.0 era of evolving manufacturing sector, efficiency and precision are very essential.

In this Manufacturing sector, Azure AI Custom Vision becomes a powerful tool that can utilize advanced image recognition capabilities to boost the production factors. This article will explore how Azure AI Custom Vision is boosting manufacturing efficiency through real-world use cases and best practices.

Let's Explore about Azure AI Custom Vision!

Azure AI Custom Vision Introduction

Azure AI Custom Vision is a service provided by Microsoft Azure that allows users to build, deploy, and improve custom image recognition models. It enables the creation of state-of-the-art computer vision models tailored to specific use cases without requiring extensive machine learning expertise.

With Azure Custom Vision, anyone can upload images, label them, and train models to recognize specific objects or features.

This service is very awesome, and it also supports both image classification and object detection, making it versatile for various applications.

Indeed, modern image classification deep learning algorithms are based on CNN, which is Convolutional Neural Network models. This in fact applies to this Azure AI Custom Vision as well, which results in effective training on custom applications and superb results!

If you want to know more about Azure Custom Vision, go ahead to our previous post here.

In this article, we will explore what ideal applications can Custom Vision do in Manufacturing sector. Let's get started!

Current applications of Azure AI Custom Vision in Manufacturing Sector

There is no deniable fact that Azure AI Custom Vision is so awesome and intelligent. Thus you may wonder what we could possibly do with this feature in Manufacturing, let's see!

The following are the current applications we could utilize the Azure AI Custom Vision in manufacturing sector as follows:

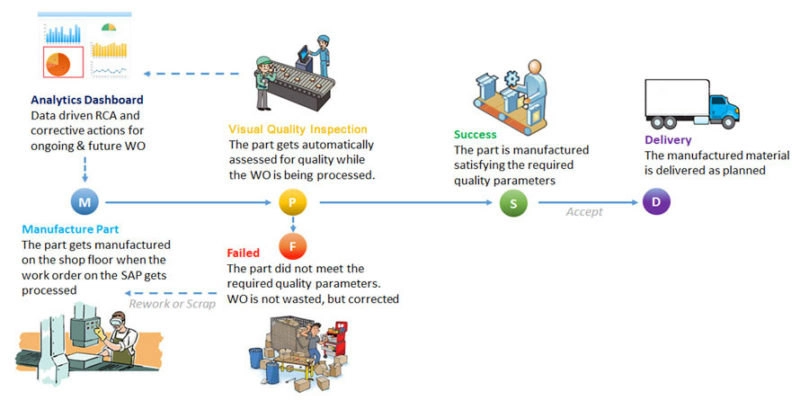

Manufacturing Sector: Quality Control with AI

- Defect Detection: Azure AI Custom Vision can be used to identify defects in products on the production line. For example, it can detect surface imperfections in automotive parts, ensuring only high-quality products reach the market.

- Consistency Checks: The technology can verify that products meet specific standards and specifications, such as checking the uniformity of paint jobs or the alignment of components.

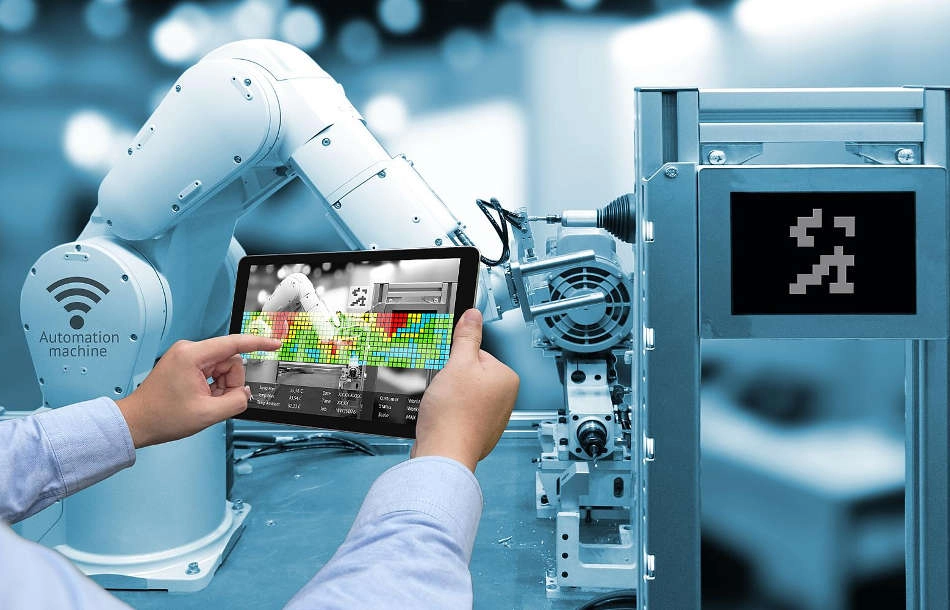

Manufacturing Sector: Predictive Maintenance

- Equipment Monitoring: Custom Vision models can analyze images of machinery to detect signs of wear and tear, enabling predictive maintenance. This helps prevent unexpected breakdowns and reduces downtime.

- Thermal Imaging: By analyzing thermal images, Custom Vision can identify overheating components, allowing for timely interventions before failures occur.

Manufacturing Sector: Inventory Management

- Automated Counting: Custom Vision can automate the counting of items in inventory, reducing manual labor and minimizing errors.

- Stock Level Monitoring: The technology can monitor stock levels in real-time, ensuring that inventory is always at optimal levels and reducing the risk of stockouts or overstocking.

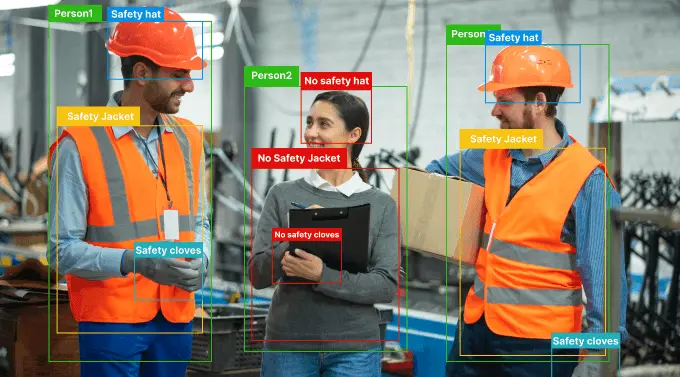

Manufacturing Sector: Safety and Compliance

- Personal Protective Equipment (PPE) Compliance: Custom Vision can ensure that workers are wearing the required PPE by analyzing images from cameras placed around the facility.

- Hazard Detection: The technology can identify potential safety hazards, such as spills or obstructions, and alert the relevant personnel to take corrective actions.

Best Practices in Manufacturing Sector for Implementing Azure AI Custom Vision

While the benefits of Azure AI Custom Vision in manufacturing are immense, it is crucial to understand and follow some best practices as follows:

Data Collection and Labeling:

High-Quality Data: Ensure that the images used for training are of high quality and representative of the real-world scenarios the model will encounter.

Accurate Labeling: Properly label the images to ensure the model learns to recognize the correct features. This may involve manual labeling or using automated tools to assist with the process.

Model Training and Evaluation:

Iterative Training: Continuously train and refine the model using new data to improve its accuracy and performance.

Integration with Existing Systems:

Seamless Integration: Work closely with IT and operations teams to ensure that the AI models integrate seamlessly with existing manufacturing systems and workflows.

User Training: Provide training to employees on how to use the new AI-powered tools effectively.

Bias Mitigation:

Diverse Datasets: Use diverse and representative datasets to train the models, reducing the risk of bias.

Security and Compliance:

Data Security: Implement robust security measures to protect sensitive data used in training and deploying the models.

CONCLUSION

Azure AI Custom Vision is transforming the manufacturing industry by enhancing efficiency, precision, and safety. By leveraging real-world use cases and following best practices, manufacturers can harness the full potential of this technology to drive innovation and maintain a competitive edge. As the industry continues to evolve, the responsible and strategic use of AI will be crucial in shaping the future of manufacturing.